🇷🇼 REPUBLIC OF RWANDA –

Tantalum, Tin & Niobium Mining Project

OVERVIEW

- Country: Republic of Rwanda (Eastern Province, near Kigali)

- Project Status: Completed

- Start Year: 2001

- Conclusion Year: 2005

- Minerals:

♦ Tantalum (Columbite–Tantalite)

♦ Tin (Cassiterite)

♦ Niobium - Ore Type: Placer (Alluvial) and Eluvial Deposits

- Geology: Deposits hosted in granite pegmatites and hydrothermal quartz veins of the Mesoproterozoic Karagwe–Ankole Belt

- Technology:

♦ Pilot EXPLORER® Portable Plant – 20 TPH (2001)

♦ Custom-designed mechanized processing plant – 120 TPH (2002), first of its kind in Rwanda

PROJECT DESCRIPTION

The Rwanda mining project was initiated in 2001, in association with Pyramid Trading Company.

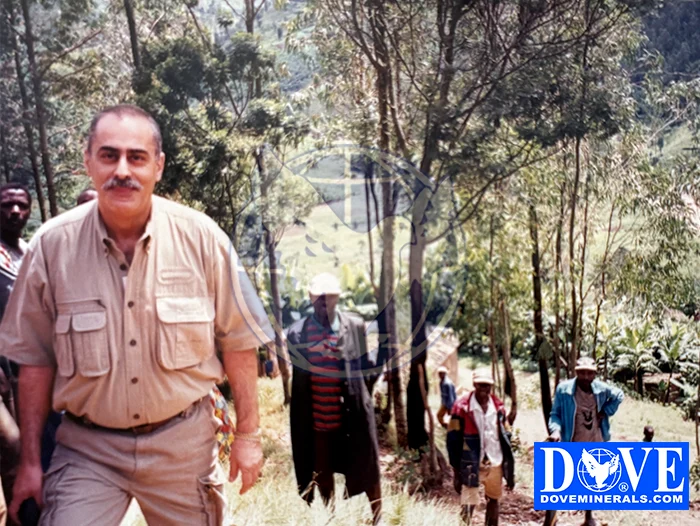

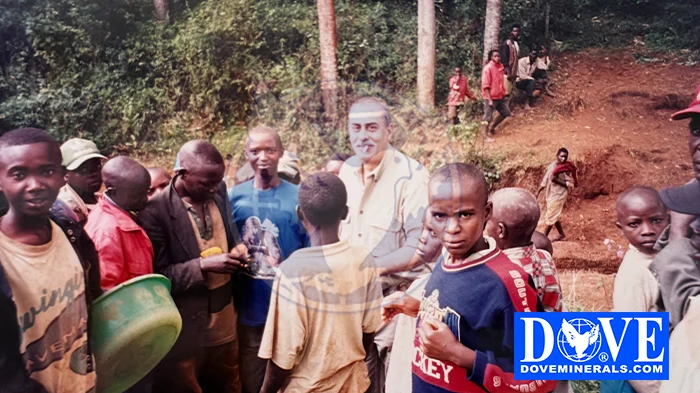

At the start of the partnership, Dr. Fillip Sharifi (CEO, DOVE) traveled to Kigali and, through reconnaissance and exploration, discovered the first significant tantalite deposit in Rwanda’s Eastern Province, approximately 2.5 hours east of Kigali.

To confirm deposit potential, DOVE installed a pilot EXPLORER® portable processing plant with a capacity of 20 TPH. This facility enabled bulk sampling, exploration-scale recovery, and provided critical engineering data for the design of a full-scale operation.

Following the pilot success, in 2002, DOVE installed a complete mechanized mineral processing plant with a capacity of 120 TPH, engineered specifically for the recovery of tantalum, tin, and niobium.

Plant Configuration & Features

The 120 TPH processing plant was custom-designed by DOVE engineers to process Rwanda’s mixed ore environment.

Key Features:

- Hydraulic “cannon monitors” to break down compact eluvial ore and wash into the feed system.

- Gravel pumping system for efficient slurry transfer.

- Trommel classifiers to remove oversize and prepare ore for separation.

- Jig concentrators for primary recovery of heavy minerals.

- VBS® (Variable Belt Speed) concentrators for secondary upgrading.

- Shaking tables and magnetic separators for final cleaning of tantalum, niobium, and tin concentrates.

This unique design ensured maximum recovery efficiency, durability in remote conditions, and low-cost operations.

Strategic & Diplomatic Impact

At the time of DOVE’s arrival, Rwanda was under strict sanctions imposed by the EU, U.S. Treasury Department, and the UN, prohibiting tantalum and tin exports. These restrictions were based on allegations that Rwanda’s exports were smuggled from DRC conflict zones.

By independently discovering Rwanda’s legitimate domestic deposits, DOVE demonstrated that Rwanda could become a transparent and self-sufficient supplier of critical minerals.

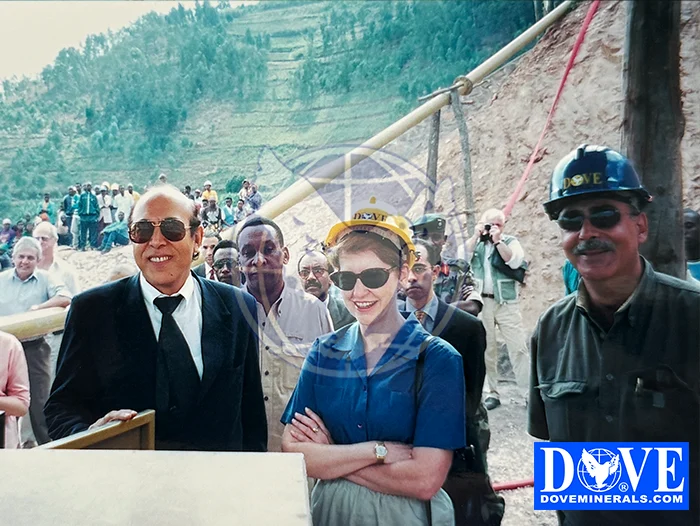

H.E. Ambassador Margaret K. McMillion with Dr. Fillip Sharifi at the inauguration

To mark this achievement, in 2002, Dr. Sharifi invited the U.S. Ambassador to Rwanda, Hon. Margaret K. McMillion, together with senior government officials, to inaugurate the 120 TPH processing plant.

- Ambassador McMillion formally started the power plant during the ceremony.

- She personally witnessed the first production of tantalum concentrates.

- This event became a historic milestone in Rwanda’s mining sector.

With U.S. government support, sanctions on Rwanda’s tantalum exports were relaxed, enabling the country to re-enter international markets as a legitimate and independent producer.

Legacy & Significance

- First mechanized tantalum–tin–niobium processing plants in Rwanda (20 TPH pilot and 120 TPH full-scale).

- Confirmed Rwanda’s independent domestic deposits, separating them from “conflict mineral” allegations.

- Catalyst for the lifting of international sanctions on Rwanda’s mineral exports.

- Positioned Rwanda as a globally recognized supplier of critical minerals for electronics and aerospace industries.

- Contributed to Rwanda becoming one of the world’s largest tantalum producers, today supplying an estimated 18–22% of global demand.

- DOVE operations in Rwanda were successfully concluded in 2005.